In the power generation industry, thermal control and management represent one of the most critical challenges. Equipment such as turbines, compressors, boilers, and piping systems are exposed to extremely high temperatures and must be properly insulated. Without adequate insulation, energy loss becomes a major issue, leading to reduced efficiency across the industry. Therefore, the use of efficient and appropriate thermal insulation is of particular importance.

Jacket Insulation: A Reliable and Eco-Friendly Option

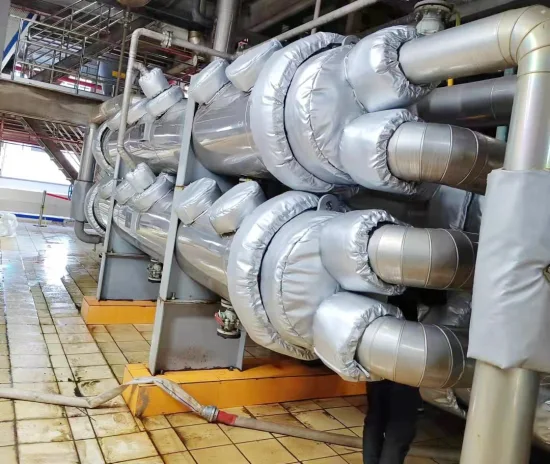

One type of thermal insulation that has gained considerable attention in recent years is jacketed insulation. These systems consist of smaller insulation components assembled together to form a complete jacket insulation system.

Jacketed insulation is produced by reputable companies like Klevers Aryana and is available in two main designs: pillow-type and cladding-type. Each has its unique features and advantages:

- Pillow-Type Design: In this design, the insulation material is placed between fabric covers and then mounted onto the equipment. This configuration increases flexibility and allows better adaptation to complex geometries.

- Cladding-Type Design: Here, the insulation material is applied directly to the equipment and covered with a metal sheet, typically made of aluminum, stainless steel, or galvanized steel. This provides greater resistance to environmental factors such as moisture and corrosion.

A key benefit of jacketed insulation is its ability to be customized based on the environmental conditions at the installation site, including temperature, pressure, and corrosive elements. Klevers Aryana uses advanced design software, thermography, and 3D modeling tools to determine the most efficient insulation layout for each project.

Beyond thermal protection, jacketed insulation is also effective in fire prevention, noise reduction, and providing resistance to corrosion and mechanical stress. These qualities make it an ideal solution for high-risk industries such as power generation.

Enhancing Efficiency and Energy Savings with Jacketed Insulation

The use of jacketed insulation in the power industry offers numerous advantages, including increased efficiency, lower fuel costs, improved workplace safety, and reduced greenhouse gas emissions. Given the high cost of energy, the savings gained from applying these insulations can quickly offset the initial investment.

Another notable feature of jacketed insulation is its high environmental compatibility. These systems do not release any toxic or harmful substances, making them a safe and sustainable choice for industrial projects.

In conclusion, with the growing adoption of jacketed insulation in the power sector, we are witnessing improvements in efficiency, cost reduction, enhanced safety, and better environmental protection. Leading companies like Klevers Aryana play a key role in this field by offering a wide range of customized products and services.