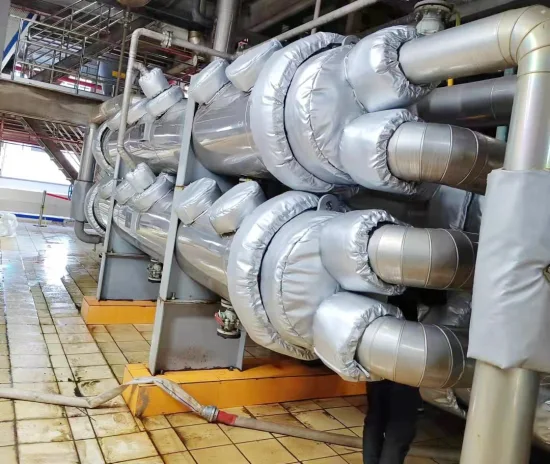

Metal expansion joints, or metallic expansion connections, are considered one of the critical components in industrial systems operating under high temperature and pressure. Due to their specific characteristics, these connections play an essential role in maintaining optimal performance and safety of pipelines and related equipment. In this article, we will introduce metal expansion joints, their advantages, applications, types, and important considerations for their selection and use.

What is a Metal Expansion Joint?

A metal expansion joint, also known as a metallic expansion connector (Metal Expansion Joint), which is also referred to as a seismic isolator in Iran, is a mechanical component designed to absorb various movements such as thermal expansion, vibrations, and mechanical changes in pipes within piping systems and fluid transfer systems. Engineers manufacture these components from metal and design them to absorb movements and stresses caused by temperature changes or other mechanical forces in industrial systems.

Metal expansion joints are primarily used in the following cases:

- Thermal Expansion and Contraction: Pipes may expand or contract due to temperature changes. Metal expansion joints absorb these longitudinal changes without damaging the system.

- Vibration Absorption: These components can absorb vibrations caused by machinery, pumps, and compressors, preventing the transmission of these vibrations to other parts of the system.

- Compensation for Mechanical Changes: In some cases, pipes may move in a specific direction due to structural displacements or pressure changes. Expansion joints compensate for these displacements.

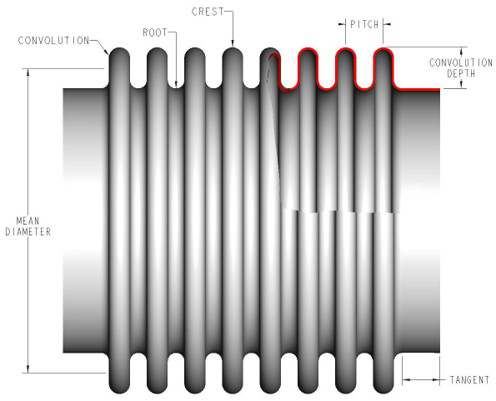

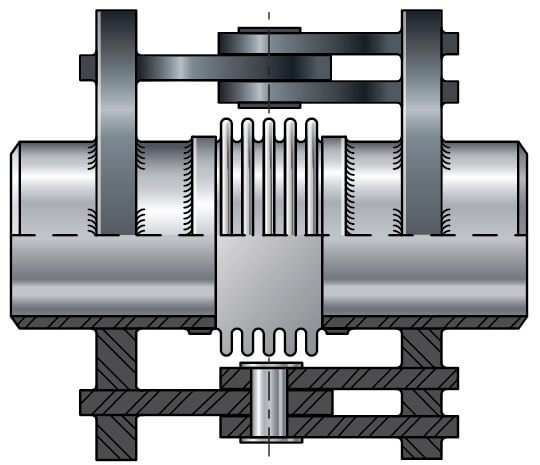

Main Components of Metal Expansion Joints

- Bellows: The most critical part of this type of connection, which is made from flexible metals such as stainless steel (to withstand necessary contraction and expansion).

- Reinforcing Rings: These rings are used to increase the strength and durability of the bellows.

- Flanges or Welded Connections: Used to install the expansion joint to pipes or systems.

These connections are used in industries such as oil and gas, petrochemicals, power plants, food industries, and even HVAC systems, helping to extend the lifespan of piping systems.

Advantages of Using Metal Expansion Joints

- High Thermal Resistance: Metal expansion joints can withstand temperatures up to 1000 degrees Celsius, making them ideal for use in high-temperature systems such as steam pipelines and flues.

- Corrosion Resistance: These connections are resistant to chemicals and corrosive substances, allowing them to operate without issues in corrosive industrial environments such as refineries and petrochemicals.

- High Pressure Resistance: Metal expansion joints can withstand pressures up to 160 bar, making them suitable for use in high-pressure systems such as gas turbines.

- High Flexibility: These connections have high flexibility and can prevent axial, angular, and lateral movements in systems.

- Long Lifespan: Metal expansion joints have a long lifespan and can operate for years without needing replacement, reducing maintenance costs.

Applications of Metal Expansion Joints

Metal expansion joints are used in various industries, including:

- Oil and Gas Industry: Used in refineries, petrochemicals, and oil and gas pipelines to manage thermal expansion and contraction of pipelines.

- Power Plants: Used in power plants to manage thermal expansion and contraction of steam pipelines and flues.

- Chemical Industry: Used in the chemical industry to manage thermal expansion and contraction of pipelines carrying corrosive chemicals.

- Food and Pharmaceutical Industries: Used in food and pharmaceutical industries to manage thermal expansion and contraction of pipelines in production lines.

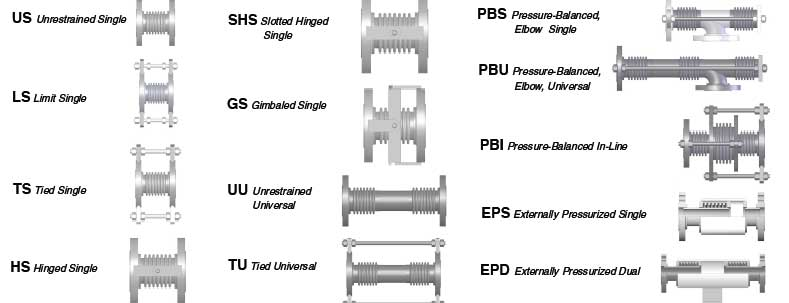

Types of Metal Expansion Joints

Metal expansion joints are divided into various types, each designed for specific applications and needs. These types include:

- Single Unrestrained Expansion Joint

- This is the simplest type of expansion joint, consisting of a bellows section and end connections. For this type, adjacent pipes must be carefully controlled regarding fixed and guiding supports, as this type of connection cannot withstand internal pressure forces.

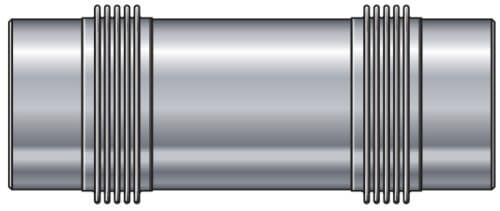

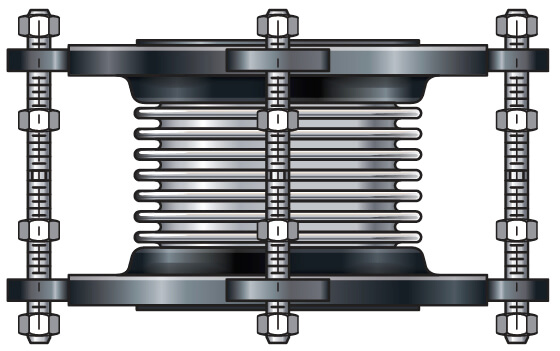

- Universal Expansion Joint

- This type has two bellows sections connected by a central pipe. This design allows for significant lateral movements and can also absorb axial and angular movements. This type also requires fixed and guiding supports to manage internal pressure forces.

- Single Tied Expansion Joint

- This expansion joint is similar to the unrestrained type, but it includes tie rods. The tie rods prevent excessive stretching of the bellows and control axial movement within a specific range.

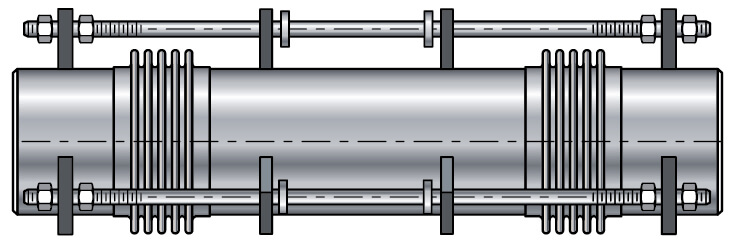

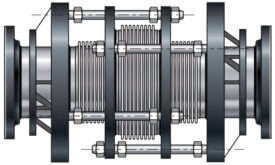

- Tied Universal Expansion Joint

- This type is similar to the universal expansion joint but includes tie rods to control internal pressure forces. By adding tie rods, internal pressure is managed, preventing the need for large fixed supports.

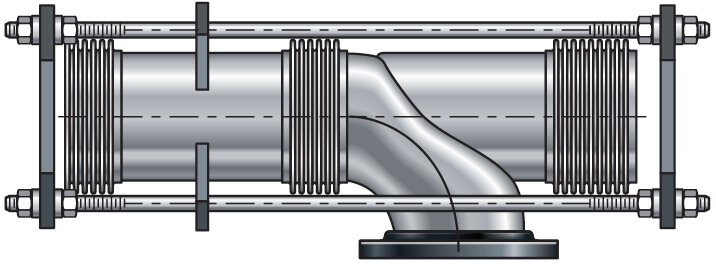

- Pressure Balanced Elbow Expansion Joint

- This type is designed to balance internal pressure while eliminating the need for fixed supports in adjacent pipes or equipment. This type can be designed as single-axis or universal depending on the need for lateral movement.

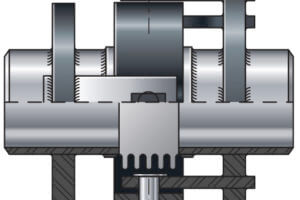

- Gimbal Expansion Joint

- This type has a bellows section and is designed to absorb angular rotation in any plane. This connection operates using two pairs of hinges connected to a central ring. Gimbal expansion joints are often used in combination with hinged expansion joints to control more complex movements.

- Hinged Expansion Joint

- This type also has a bellows section and is designed to allow angular rotation in a specific plane. The hinged sections in this connection prevent axial movement and allow it to move only in one angular direction. This type is also often used in combination with gimbal expansion joints or in triplet assemblies.

- In-line Pressure Balanced Expansion Joint

- This type has an unusual design and can absorb lateral, axial, and angular movements. It is suitable for situations where installing fixed supports is not feasible or where pressure loads on equipment such as pumps and turbines are very high.

Each of these types of metal expansion joints is designed for different conditions in piping systems, and the choice of the appropriate type depends on application conditions, required movements, and existing pressures in the system.

Guide to Selecting Metal Expansion Joints

To select the appropriate type of expansion joint for your application, consider the following points:

- Type of Fluid Flowing: The type of fluid, its chemical composition, and its corrosiveness should be considered in selecting the type of connection.

- Temperature of the Fluid: The temperature of the fluid, considering thermal shock, should be taken into account.

- Pressure of the Fluid: Metal expansion joints are suitable for high pressures.

- Amount of Movement Required from the Connection: The amount of movement required from the connection should be considered in its selection.

- Type and Amount of Abrasive Particles in the Fluid: The type and amount of abrasive particles in the fluid should be considered.

- Environmental and Weather Conditions at the Installation Site: The environmental and weather conditions at the installation site should be considered in the selection.

Below is a table comparing different types of metal expansion joints. The columns in this table are selected based on the type of permitted movements, need for fixed supports, and common applications:

| Type of Expansion Joint | Permitted Movement | Internal Pressure Restraint | Need for Fixed Supports | Axial Movement | Lateral Movement | Angular Movement | Common Applications |

|---|---|---|---|---|---|---|---|

| Single Unrestrained | Axial | Requires fixed support | Very Important | Yes | Limited | No | Simple lines with limited temperature changes |

| Universal Expansion Joint | Lateral, Axial, Angular | Requires fixed support | Very Important | Yes | Yes | Yes | Piping systems with large movement variations |

| Single Tied Expansion Joint | Controlled Axial | Yes | Important | Yes | Limited | No | Systems requiring precise control of axial movement |

| Tied Universal Expansion Joint | Lateral, Axial, Angular | Yes | Medium | Yes | Yes | Yes | Applications with high pressures and need for internal pressure control |

| Pressure Balanced Elbow | Lateral, Angular | Balances pressure | Low or none | Limited | Yes | Yes | High-pressure systems and elbow piping |

| Gimbal Expansion Joint | Angular (in any plane) | Yes | Important | No | No | Yes | Systems needing complex angular rotation |

| Hinged Expansion Joint | Angular (in one plane) | Yes | Important | No | No | Yes | Applications needing angular movement in one direction |

| In-line Pressure Balanced | Axial, Lateral, Angular | Balances pressure | Low or none | Yes | Yes | Yes | Equipment like pumps and turbines with high pressure loads |

Notes:

- Permitted Movement: Indicates the type of movements (axial, lateral, or angular) that the expansion joint can absorb.

- Internal Pressure Restraint: Indicates whether the expansion joint can manage internal pressure forces without the need for fixed supports.

- Need for Fixed Supports: Indicates whether the system requires fixed and guiding supports. This is crucial for controlling forces caused by pressure.

- Common Applications: Common applications for each type of expansion joint.

This table helps in selecting the best type of expansion joint based on the specific needs of a piping system. Klevers Aryana Company, with several years of experience in manufacturing and supplying metal expansion joints, offers ideal solutions tailored to your needs. I recommend consulting with specialists in this field before taking any action through this link.

Material and Used Materials

The material of metal expansion joints is selected based on their operating conditions. The most common materials used include stainless steel, nickel-based alloys, chrome steels, and carbon steel.

Installation and Maintenance

Metal expansion joints should be installed by experienced professionals to ensure their proper and safe operation. Additionally, periodic inspection and maintenance of these connections are essential to maintain their lifespan and prevent sudden failures.

Buying Guide

Klevers Aryana Company, with several years of experience in manufacturing and supplying metal expansion joints, offers ideal solutions tailored to your needs. For more information, please read this page. To receive free consultation, contact the experts at Klevers Aryana.