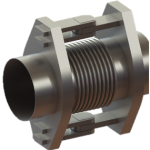

Metal Expansion Joints: An Ideal Solution for High Temperature and Pressure Systems

Metal expansion joints are a type of flexible connector used to accommodate thermal expansion and contraction in high-temperature and high-pressure systems, such as steam pipelines, chimneys, and gas turbines.

Advantages of Using Metal Expansion Joints

- High Thermal Resistance: Metal expansion joints can withstand temperatures up to 1000 degrees Celsius.

- Corrosion Resistance: These joints are resistant to chemicals and corrosive substances.

- High Pressure Resistance: Metal expansion joints can withstand pressures up to 160 bar.

- Flexibility: These joints offer high flexibility and can prevent axial, angular, and lateral movements in systems.

- Long Lifespan: Metal expansion joints have a long lifespan and can operate for years without needing replacement.

Applications of Metal Expansion Joints

- Oil and Gas Industries: These joints are used in refineries, petrochemical plants, and oil and gas pipelines to manage thermal expansion and contraction in pipelines.

- Power Plants: Metal expansion joints are used in power plants to manage thermal expansion and contraction in steam lines and chimneys.

- Chemical Industries: These joints are used in chemical industries to manage thermal expansion and contraction in pipelines carrying corrosive chemicals.

- Food and Pharmaceutical Industries: Metal expansion joints are used in the food and pharmaceutical industries to manage thermal expansion and contraction in production lines.

Types of Metal Expansion Joints

Metal expansion joints come in various types, including:

- Hinged Joints: These joints are suitable for systems with angular movements.

- Universal Joints: These joints are suitable for systems with axial, angular, and lateral movements.

- Bellows Joints: These joints are suitable for systems with significant axial movements.

- Gimbal Joints: These joints are suitable for systems with torsional movements.

Materials Used in Metal Expansion Joints

The material for metal expansion joints is selected based on their operating conditions, including:

- Stainless Steel: Suitable for high-temperature and corrosive systems.

- Nickel-Based Alloys: Suitable for extremely high-temperature and corrosive systems.

- Chromium Steels: Suitable for high-temperature and acidic systems.

- Carbon Steel: Suitable for low-temperature and pressure systems.

Considerations for Selecting and Using Metal Expansion Joints

- Type of Fluid Passing Through: The type of fluid, its chemical composition, and its corrosiveness should be considered when selecting the joint type.

- Temperature of the Fluid: The temperature of the fluid, including thermal shocks, should be considered.

- Pressure of the Fluid: Metal expansion joints are suitable for high-pressure applications.

- Required Movements: The required movements of the joint should be considered during selection.

- Type and Amount of Abrasive Particles in the Fluid: The type and amount of abrasive particles in the fluid should be taken into account.

- Weather and Environmental Conditions at the Installation Site: The weather and environmental conditions of the installation site should be considered when choosing the joint.

- Installation: Metal expansion joints should be installed by experienced professionals.

- Inspection and Maintenance: Metal expansion joints should be periodically inspected and repaired or replaced if necessary.

Klevers Aryana Company, with several years of experience in the production and supply of metal expansion joints, offers ideal solutions tailored to your needs.

For more information and to receive free consultation, contact the experts at Klevers Aryana.